Contact us today for your Free Quote

Bywaters and the Francis Crick Institute (‘The Crick’) share a vision; “to manage all waste in a holistic and sustainable manner”. However, this would not be a simple achievement. The Crick is Europe’s largest biomedical research laboratory, carrying out an incredible amount of scientific research whilst striving to reduce their burden on the environment.

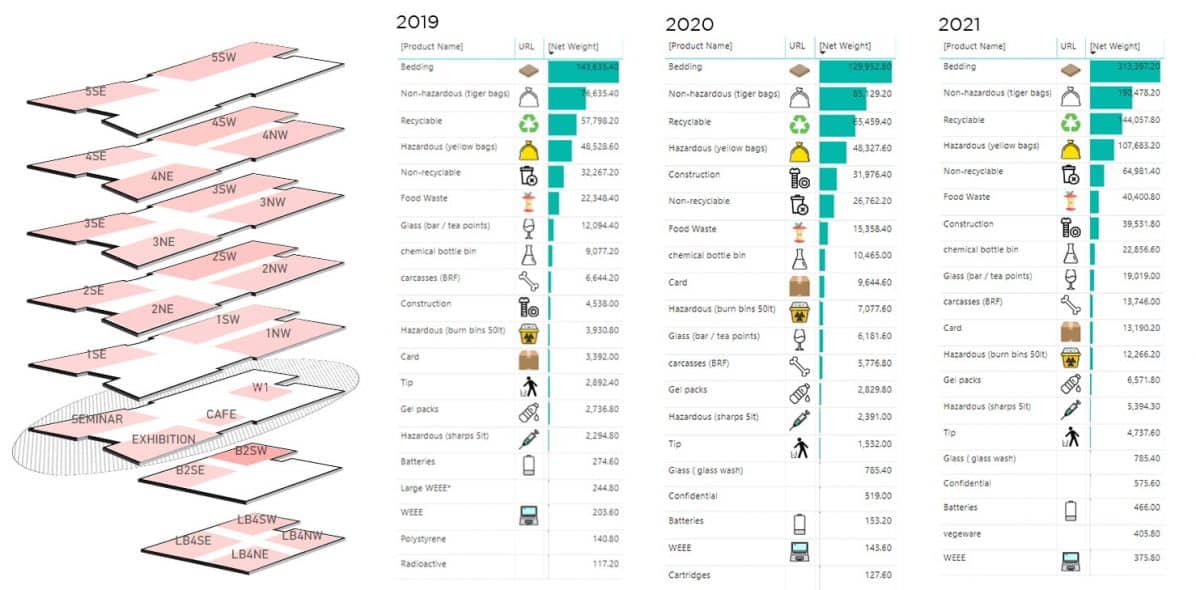

This in itself presents significant challenges, as the nature of The Crick’s work produces 25 individual waste streams (from general and food waste to clinical and radioactive materials), which have to be captured and disposed of compliantly and safely. Our partnership started in 2015 by providing support and guidance with the internal waste management set up (waste mapping) and subsequently implemented collection and disposal services for all waste streams produced at the Crick.

The Tasks

Bywater was tasked to develop a waste management system that could be seamlessly integrated within the Crick to support their research. To do so, Bywaters needed to encourage an ethos of collaboration by embedding Bywaters standards within ‘the Crick family’, and proactively identify innovative methods to support and enhance the Crick’s environmental commitment. Essentially designing their entire waste management plan from the ground up.

Our Solution

From 2016, Bywaters has been providing a ‘cradle to grave’ waste collection service from source to disposal, to increase efficiency and maximise the recycling rate in line with the Cricks recycling target of 75%.

For the Crick’s Biological Research Facility, Bywaters identified an efficient and environmentally-friendly method to recycle uncontained animal bedding. This material is treated through IVC. Ensuring the composting process takes place in an enclosed and controlled environment to ensure that any pathogens present in the waste material are destroyed. The end product can be used for land remediation.

To help increase The Crick’s recycling efficiency, Bywaters integrated custom waste containers to capture both recyclables and general waste whilst occupying the space of a single bin. They also implemented bespoke desktop bins for pipettes and testing equipment (miniaturised clinical waste containers), to help increase waste segregation without taking up floor-space.

Reuse schemes of non-hazardous items (tip boxes, cardboard, polystyrene, and wooden pallets) were also introduced. A process that enables the Crick to make the most of their waste resource before sending it to the supplier (close loop) for recycling or MRFs for further treatment.

Bywaters modified a standard compactor to be more efficient whilst still complying with site restrictions around weight, space and noise. The modified machine is ⅓ the size of a normal compactor, but can process the same quantity of material and be transported on bespoke trailers, improving mobility.

To help increase overall recycling rates, behavioral change was necessary. Bywaters and The Crick’s sustainability team offer workshops and waste training to employees.

The Outcome

Bywaters have made lasting contributions to The Crick that fully resonate with their ideology. Bywaters completely overhauled their waste management programme – floor by floor – achieving zero waste to landfill and making The Crick the only research facility in London to compost uncontained animal bedding and to send laboratory offensive waste to energy recovery.

The Crick produces over 820 tonnes of waste per year.

Waste per year

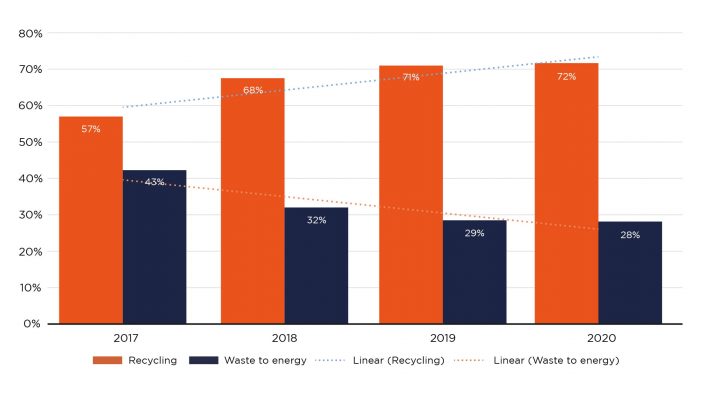

Between 2017 – 2020 our recycling has increased 26.3%, currently standing at 72%. We have seen a steady increase year on year. We have decreased waste diverted to energy recovery by 35%, which currently stands at 28%.

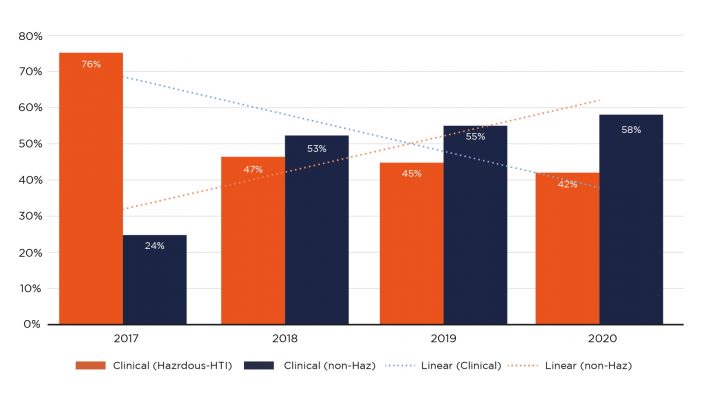

Laboratory waste per year

From the beginning of our partnership with The Crick, we have increased clinical waste diverted to energy recovery (non haz waste) by 142% and decreased clinical high temperature incineration waste by 45%.